Printing for Prototypes

- Quickly prototype parts, sometimes as fast as next day.

- Efficiently test and refine product designs before scaling up production.

- Save money by verifying 3D printed parts before committing to more expensive processes.

Printing for Manufacture

- Reduce production costs by minimising waste.

- Eliminate the need for expensive moulds or tooling.

- Produce complex and intricate designs that traditional manufacturing methods can’t.

- Open up new possibilities for innovative product designs.

- Shift to a more agile production model with on-demand manufacturing, reducing the need for large inventories and minimising overproduction.

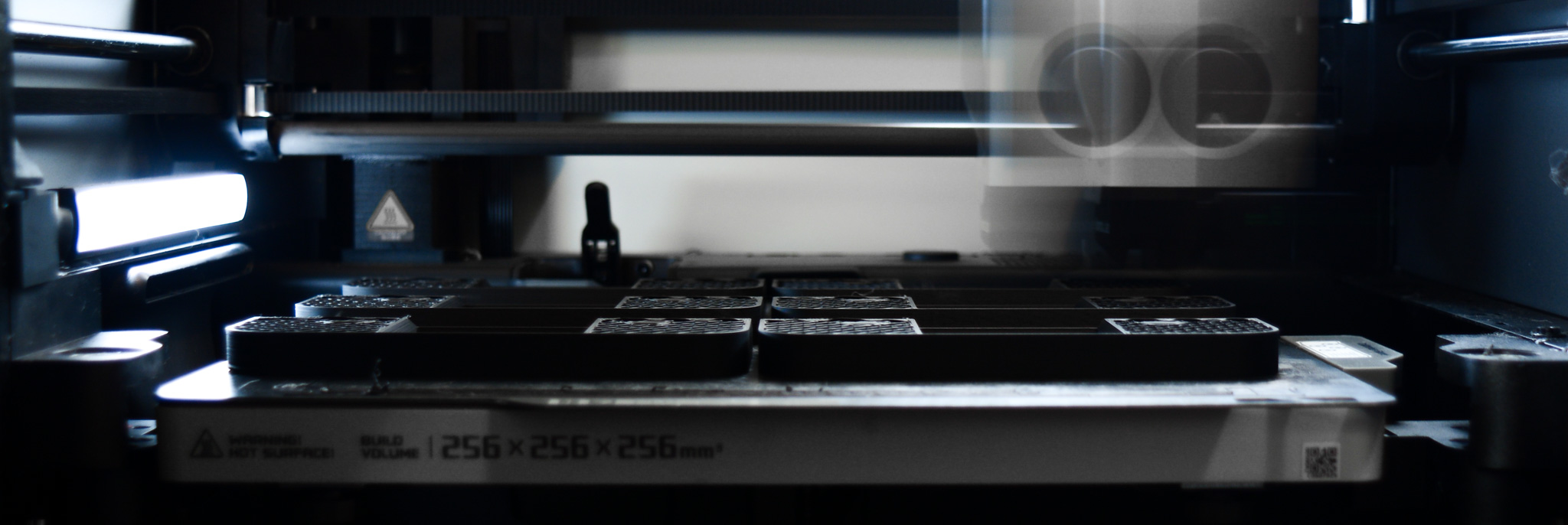

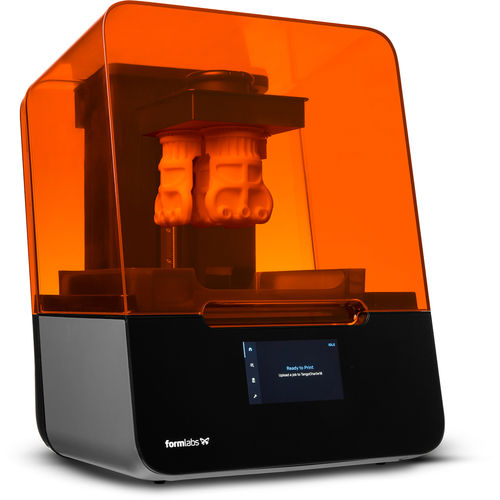

We have two different types of machine: FDM and SLA

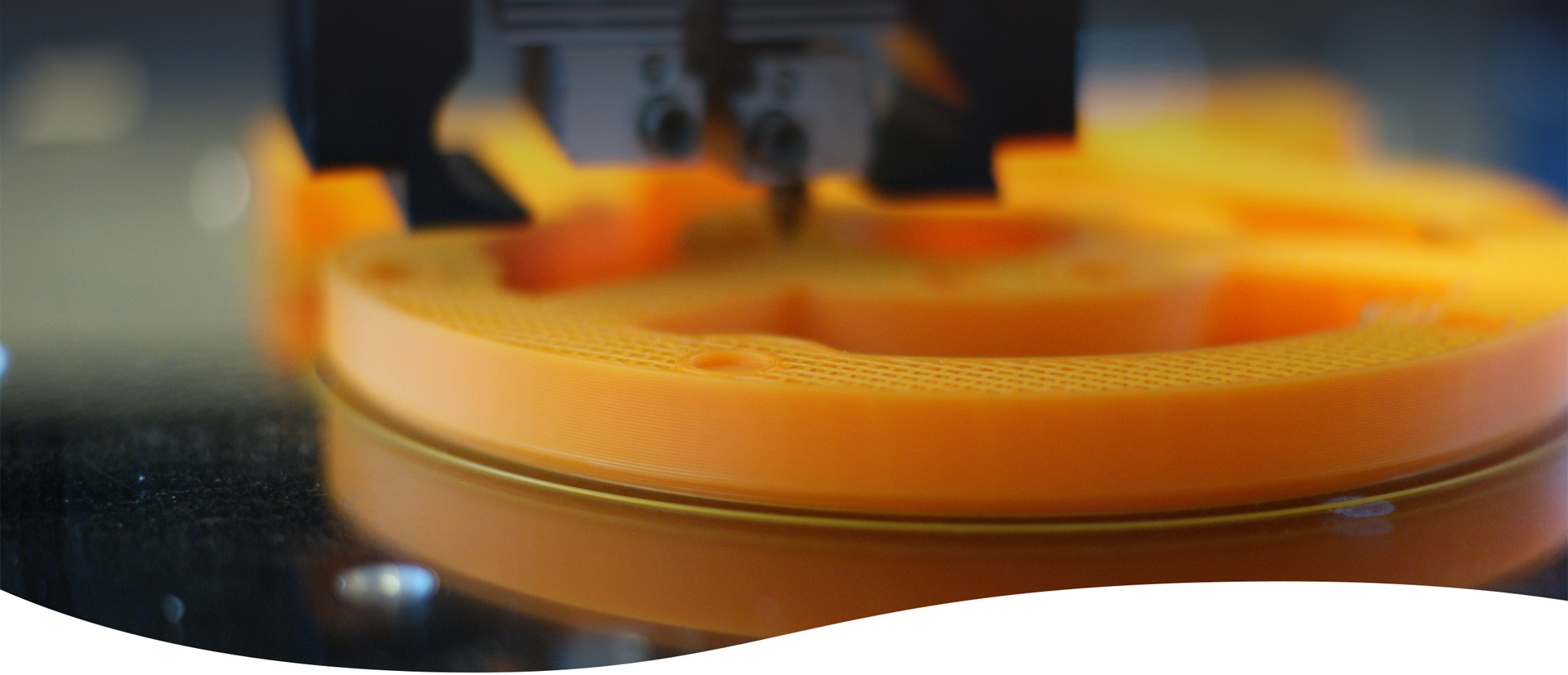

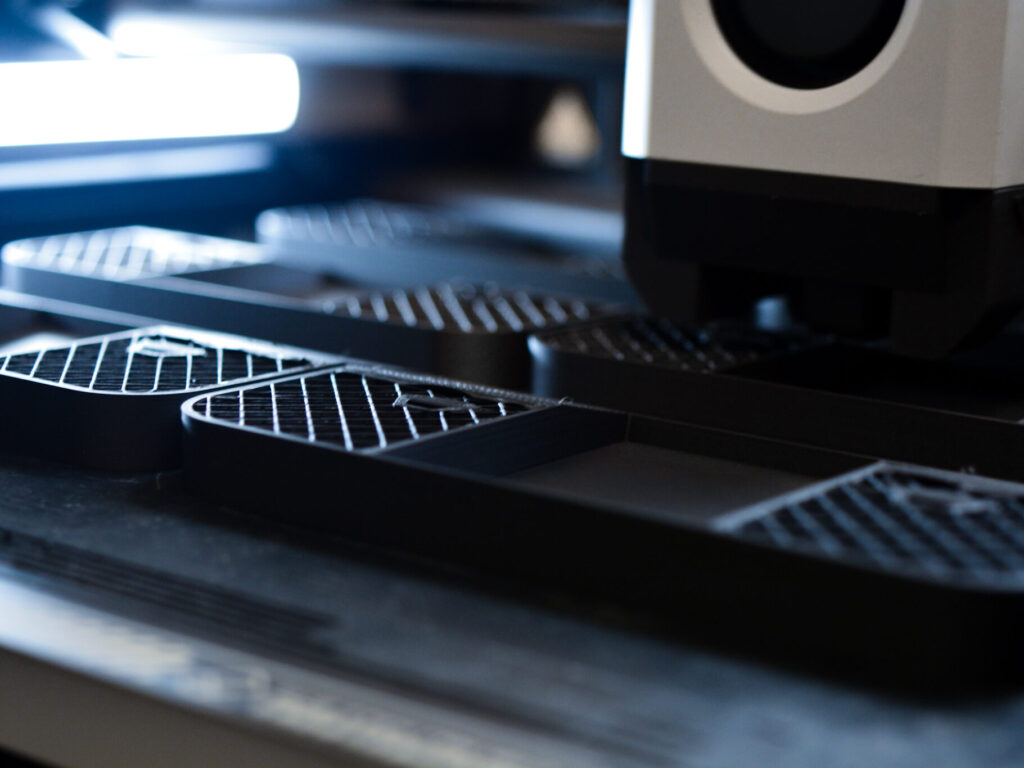

We use Fused Deposition Modelling (FDM) 3D printing as a manufacturing method. This can be used to create fast prototypes and production pieces.

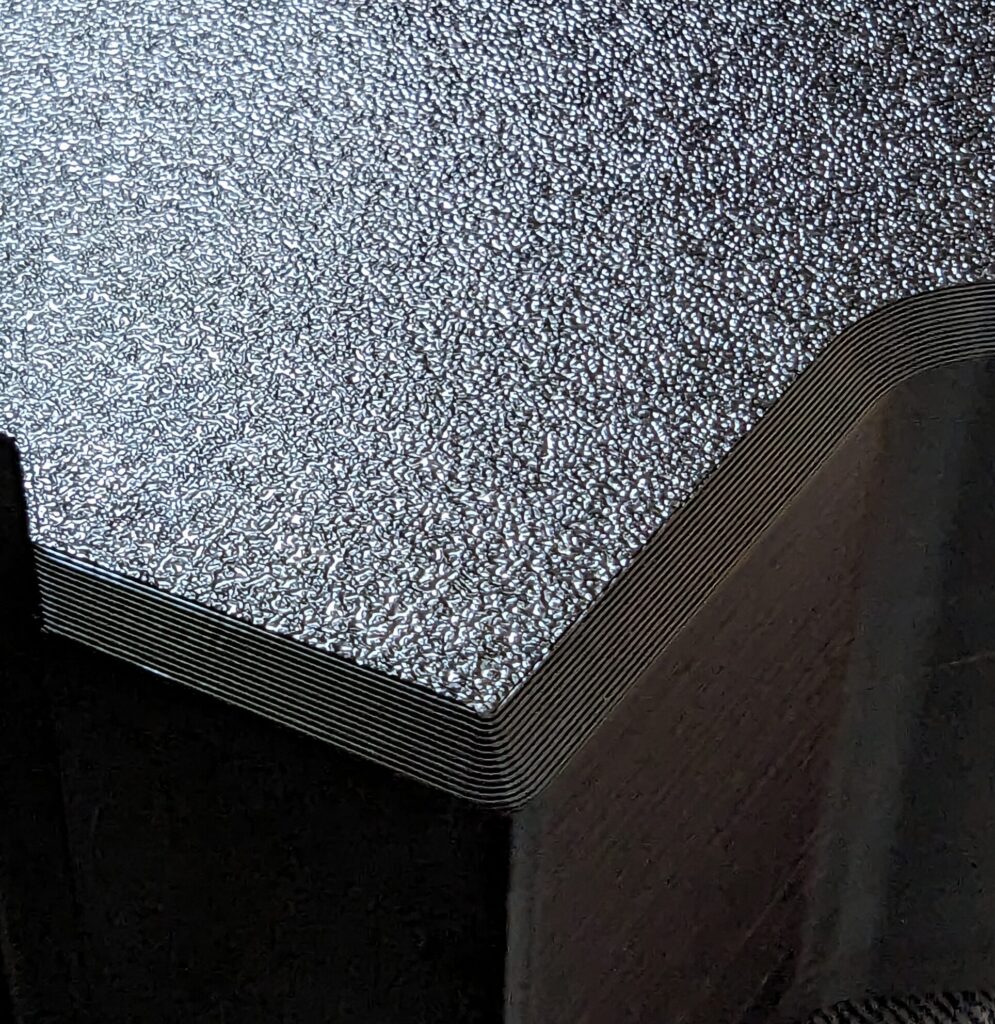

Stereolithography (SLA) 3D printing, differs significantly from Fused Deposition Modelling (FDM). Unlike FDM’s layer-by-layer deposition of thermoplastics, SLA employs a liquid resin cured by ultraviolet light to create precise, high-resolution objects. SLA’s process results in smoother surfaces and finer details, making it ideal for intricate prototypes and manufactured pieces.